Textile

Architecture

Hardware Specification

Function Modules

Architecture

Hardware Components and Installation Deployment:

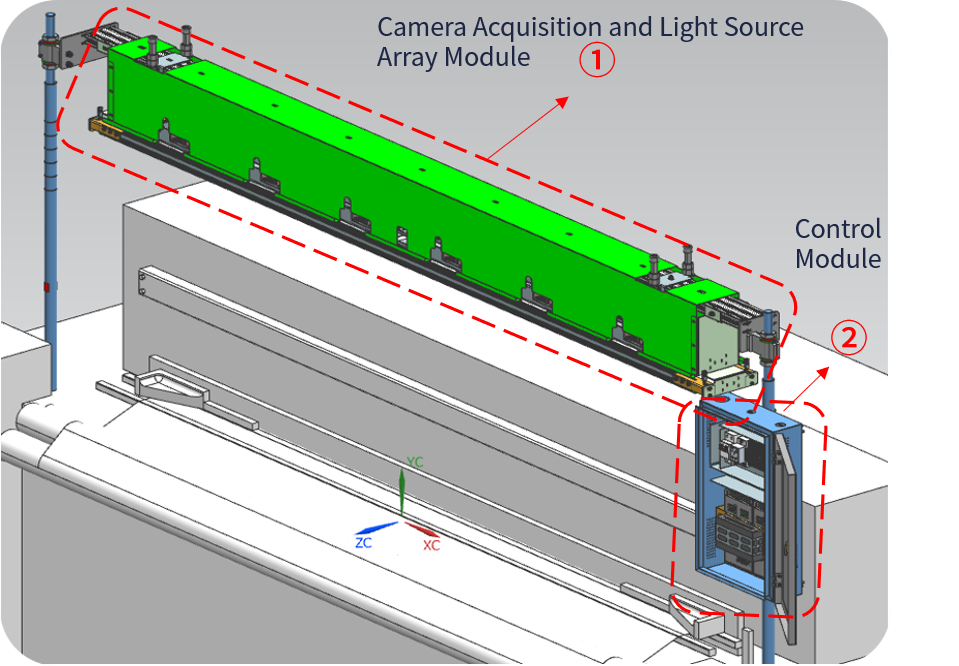

The greige fabric inspection solution provided by APLUX includes two main components:

I. Camera Acquisition and Light Source Array Module

Device Installation:Mounted via lifting holes and mounting columns.

The light source and camera are installed on a crossbeam directly above the air-jet loom at a height of 100 cm from the fabric surface.

No floor drilling required (easy and straightforward installation).

II. Control Module

Device Control:Collects weft insertion data from the loom via RS485 communication and opto-isolators.Triggers automatic equipment halt during defect detection.

Hardware Specification

SoC:

Qualcomm QCS6490learn more | |

|---|---|

| CPU | 1×A78@2.7GHz 3×A78@2.4GHz 4×A55@1.9GHz |

| AI | 12 INT8 TOPS |

| GPU | Adreno 643 @812MHz |

| WIFI | 802.11ax, 2.4G/5G DBS, 2*2 MIMO |

| BT | 5.2 |

| Encoder | 4K @30 fps |

| Decoder | 4K @60 fps |

Memory & Storage:

| RAM | 8GB |

| ROM | 128GB |

Mainboard interfaces required:

| USB-A | 3×2.0 |

| USB-C | 1×3.0, with DP |

| HDMI_OUT | ×1 |

| LAN | 1×Gigabit Ethernet |

| RS485 | ×1 |

Full specification of the reference main board, pls check in <Get>

Function Modules

- The system can record fabric defects on demand and precisely locate defect coordinates. It can halt equipment operation upon detecting critical defects.

- It automatically grades various defect types according to customer standards (e.g., AA grade, A grade, B grade, etc.), generating comprehensive roll evaluations.

- Fabric length measurement: Utilizes DTU for real-time length tracking to mark defect positions and dimensions accurately.

- Full-process documentation of operator actions and procedures ensures complete traceability.

- Automatically generates inspection reports with QR codes for each roll, which are printed and affixed to fabric surfaces.

- The defect management system integrates with ERP/MES/CRM/SRM systems and enables data exchange with back-end winding machines.